Efficient content of each constituent in an optimized brake friction material. An acceptable brake pad material must have the following characteristics.

Friction Materials What Are They How Do They Work Types

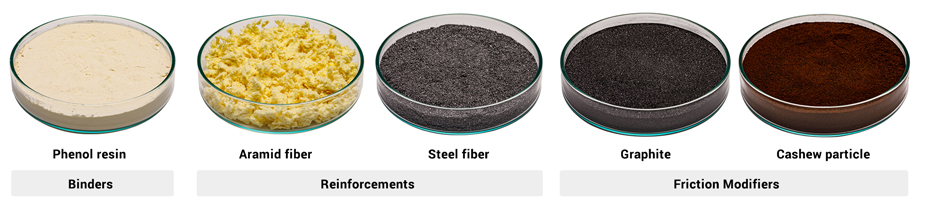

List of raw materials need for sample preparation.

. It also contains no toxic materials. The materials used for the brake systems must meet the following criterias. Years ago a brake replacement would pass muster if it allowed a vehicle to stop in a reasonable distance at highway speeds.

For high energy and continuous slip applications wet is preferred over dry since the frictional heat is removed more effectively with oil than air. 4 A brake friction material manufacturer that knowingly violates this chapter must recall the brake friction material and reimburse the brake friction distributor retailer or any other purchaser for the material and any applicable shipping and handling charges for returning the material. The amount of asbestos in brake friction material is being restricted because.

The choice of brake lining compound depends on the application. Only applies to brake friction materials for vehicles as defined in the California Vehicle Code. Automotive Brake DrumRegulatory compliance for friction material labeling is required in the sates of California and Washington.

Brake friction material must meet which of the following criteriaquick recovery from heat fading quick recovery from heat fading resistance to water fading and resistance to heat fading. Promote the Copper-free Brake Initiative and phase-out of the following constituents in motor vehicle brake friction materials on a national basis. Ecology will reject certification documents with edge codes that clearly do not comply with SAE J866 such as LW or 9769.

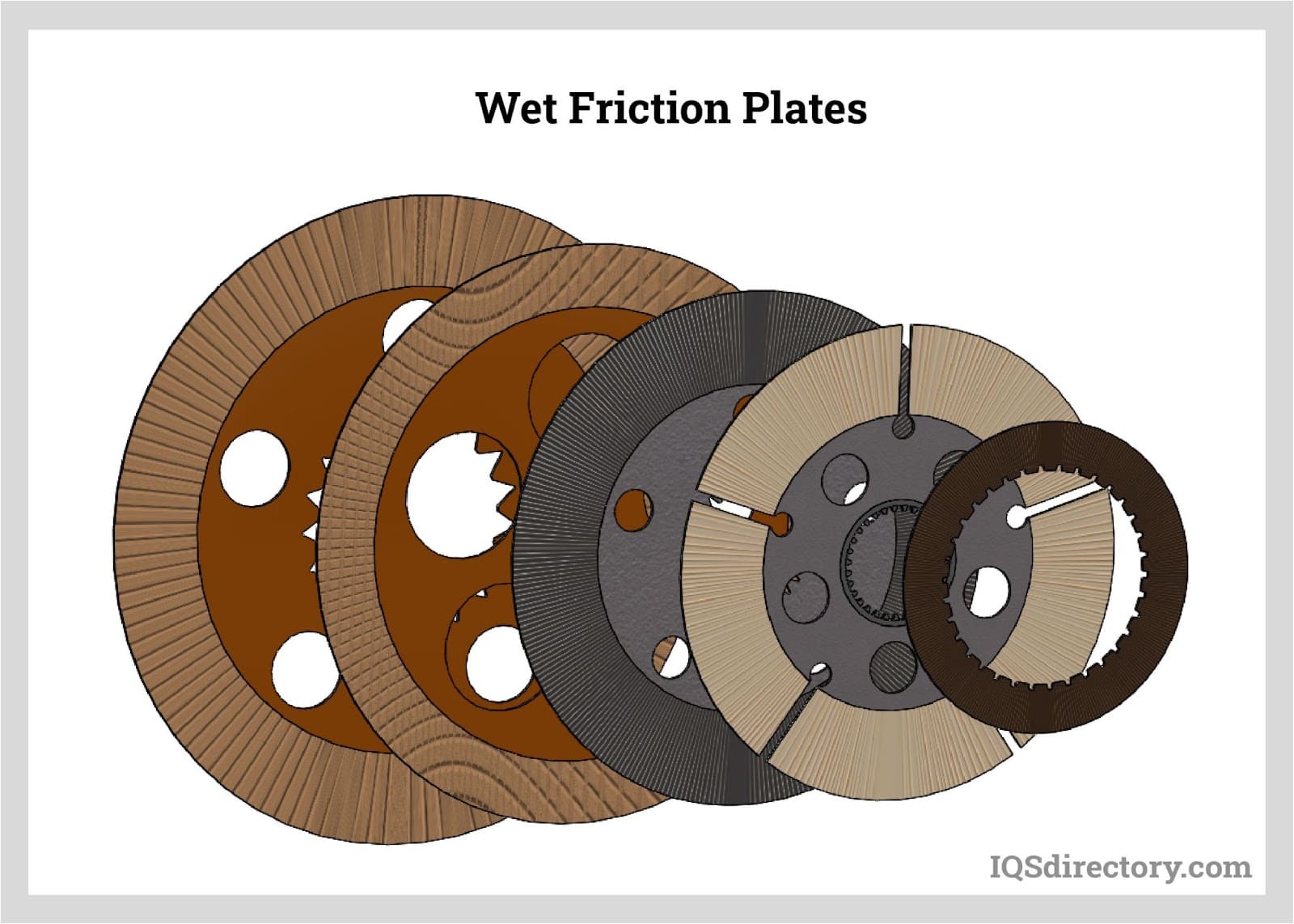

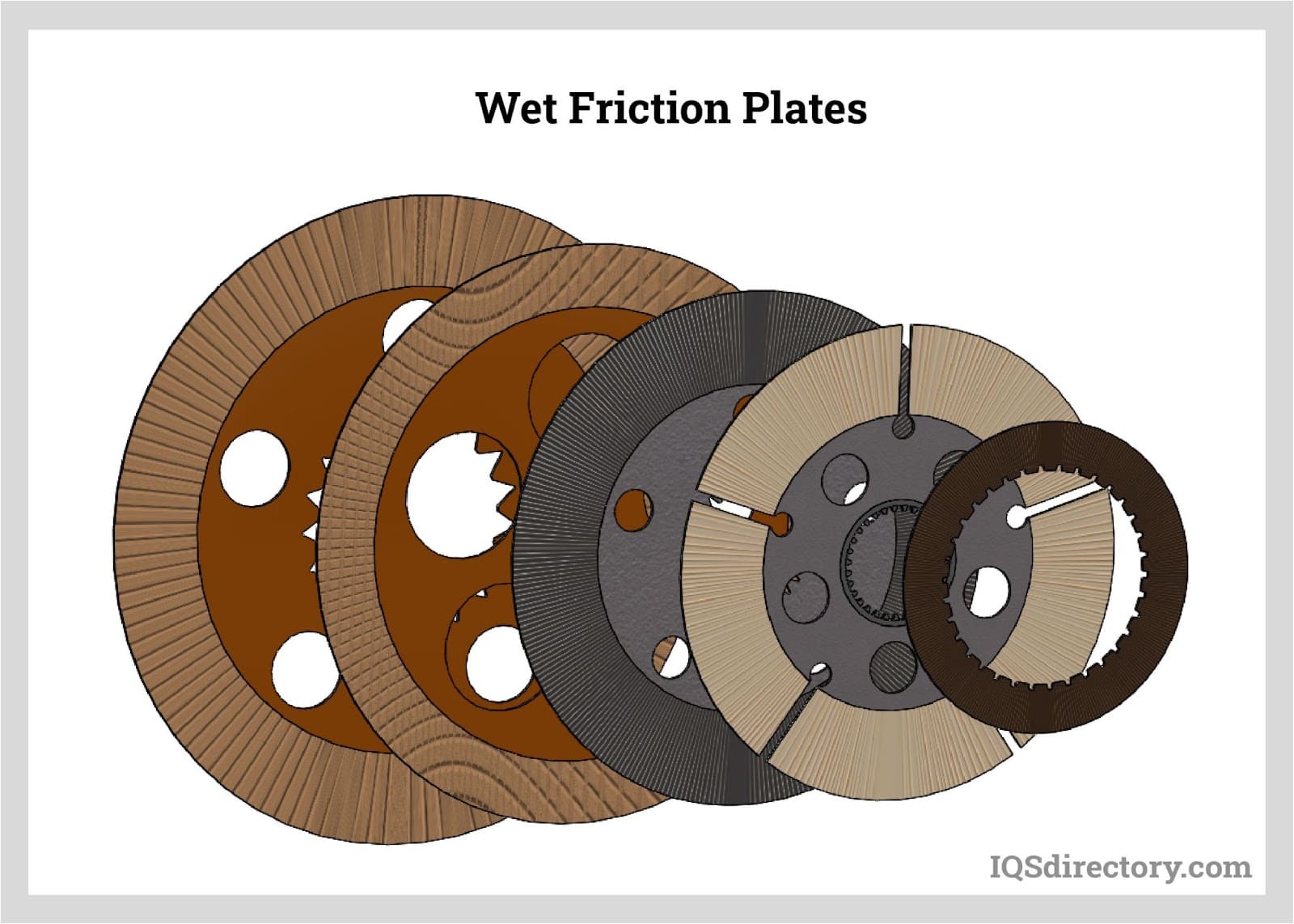

Friction materials that operate in fluid media are called wet friction materials WFMs. Regardless of what type of friction material is used in a set of pads or shoes the brakes must provide safe reliable stopping power. The coefficient of friction depends on the materials used 2.

Beginning January 1 2014 brake friction material containing the following constituents exceeding specified quantities may not be sold in the state. Most do and the brake manufacturers do extensive laboratory and field testing to ensure that they do. Similarly Naemah 2011 reported that a good brake pad material must meet the following criteria.

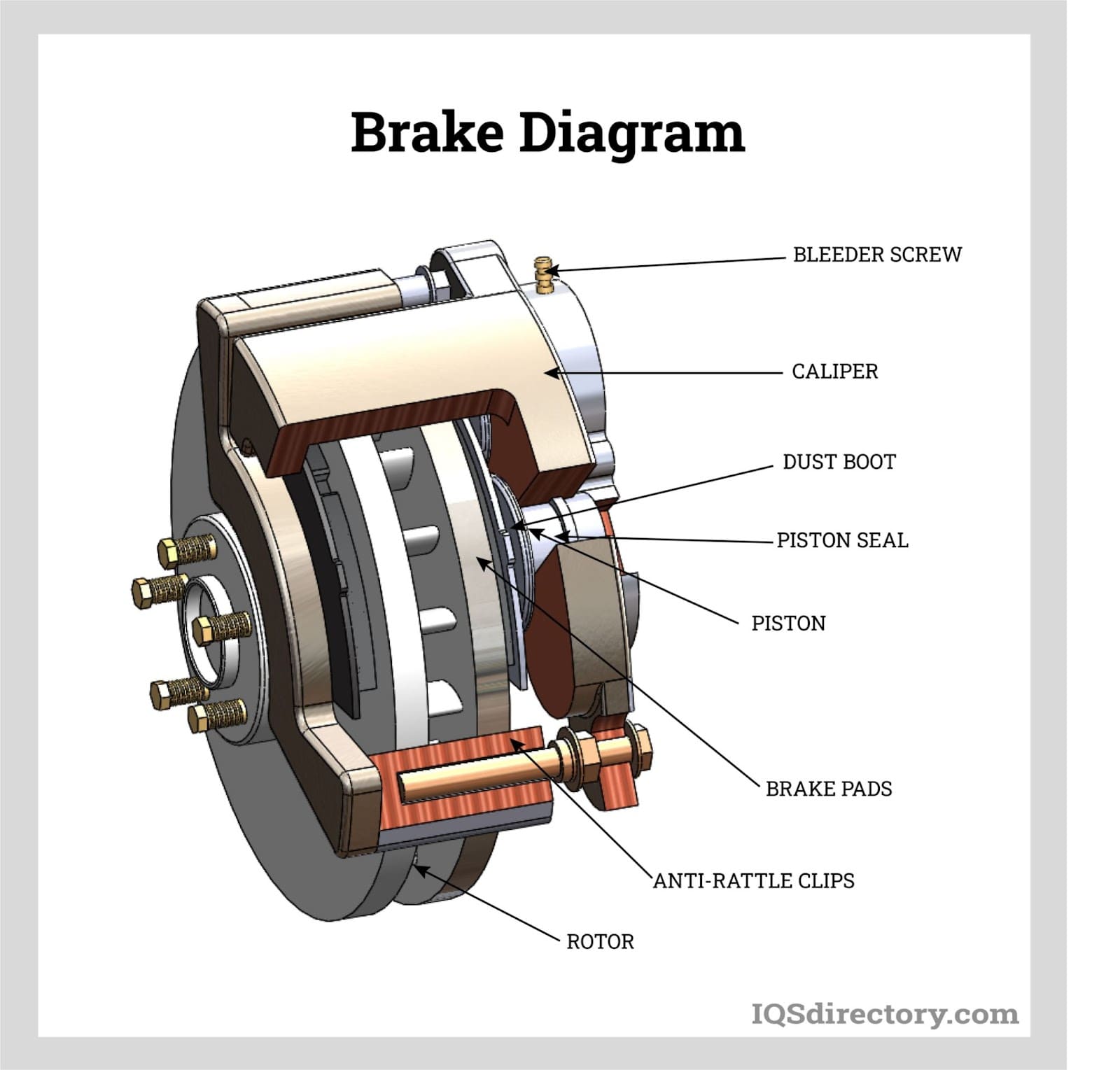

A manufacturer of brake friction material shall submit a sample of brake friction material to a laboratory approved by the testing certification agency to perform testing in accordance with California Code of Regulations title 22 section 663875. Firstly it is made of ST-41 steel plate and is constructed to transmit the braking force to the composite material. Today a brake replacement must meet consumer-oriented criteria in areas of braking noise pedal sensitivity side-to-side pulling pedal pulsation frictional qualities fade resistance wheel dusting and friction longevity.

The materials must have a good resistant to. Semimetallic materialsA higher quantity of steel copper andor brass. It must have a high kinetic coefficient of friction.

The labeling requirements apply to metallic. This is a patent for a friction material other than asbestos. Which technician is correct.

WFM is a compressible porous and permeable material that operates in oil. List of raw constituents is shown in table 1. Markings on your brake friction material must match what you report to us when certifying your product.

You must report the manufacturer identifier and the friction formula identifier. The material used is a serpentine-steel composite. Hydraulic systems can be used to.

Flexible brake hose should be inspected for all of the following except. 1 After January 1 2015 self-certification documentation submitted to the department under WAC 173-901-060 will fulfill brake friction materials manufacturers reporting requirements under RCW 70285070. Copper asbestiform fibers cadmium and its compounds chromium VI-salts lead and its.

Goal of formulation is optimizing to meet the required criteria such as low wear as well as a stable and desired friction level of different braking circumstances 34. Constituents of wet friction materials include fibers fillers and resins. Ceramic materialsCeramic fiber materials and possibly a small amount of copper.

The hardness of the material is lower than the wheels. There are specific exemptions listed in HSC section 2525055. Produced and tested to see if they meet certain criteria to be used as brake pads.

Technician B says that the power-assisted brake system reduces the force that the driver must exert on the brake pedal. Low-metallic NAO materialsSmall amounts of copper or steel and NOA materials. Testing of all unique part numbers are required for compliance to the regulations by a laboratory approved to provide such analysis per SAE J2975.

2 By January 1 2013 manufacturers of brake friction material. Good thermal conductivity good corrosion strengt h low noise low weight long durability steady friction. Ideally the materials used to make brake systems must meet the following criteria.

Ideally a set of aftermarket replacement linings will perform the same as or better than the OEM linings. A brake friction material manufacturer that violates this chapter is subject to a civil penalty not. The frictional value must be stable over a temperatures and pressures range.

Good thermal conductivity good corrosion strength low noise low weight long durability. First California Health and Safety Code HSC sections 2525050 etseq. It must be environmentally acceptable and be safe for use.

The result of their study showed that the selected reinforcement materials were comparable with other commercially available brake pad materials. Ideally the materials used to make brake systems must meet the following criteria. There are no specific exemptions for heavy duty vehicles under the California law.

Good thermal criteria resistance to corrosion lightweight long durability low noise stable friction low wear rate and acceptable c ost versus performance. Reporting requirements for brake friction material manufacturers. Submit a sample of each manufactured brake friction material for laboratory testing.

The materials must have a good high heat capacity thermal conductivity and good thermal properties and also be able to withstand higher temperatures and high contact pressures The materials must exhibit a high frictional coefficient. It causes no strong smell in friction. Backing plate Backing plate for a trains composite brake block must meet the following criteria.

Brake friction material that is part of a brake friction material manufacturers distributors or.

Friction Materials Brakes For Automobiles Product Products And Technologies Akebono Brake Industry Co Ltd

Friction Materials What Are They How Do They Work Types

Friction Materials Brakes For Automobiles Product Products And Technologies Akebono Brake Industry Co Ltd

0 Comments